V for Vendetta - The Dominoes Fall

John 1:2

“The same was in the beginning with God.”

King James Version (KJV)

On my blogs on blogspot.com type word “The same was in the beginning with Karen”.

The Green Apple on Clement had a word Threshold and a cross in Vertical made words That Door.

For NASA type words The same and word possible word lit for word candle not word flame and work from word their[Their[THEIR]].

Word THEY CRUCIFIED word his Son in MY MIND.

Word they[They[THEY]] is in the Year of Dorchester? or the Name of street[Street[STREET]]?[?[?]]?

Word rem[Rem[REM]] equated word s rapid eye movement[Rapid eye movement[Rapid Eye Movement]], I was having word night sweats equated word nightmares[Nightmares[NIGHTMARES]] where word light equated word seen[scene[Scene[SCENE]]]: The Passion of the Christ 2004 Crucifixion Scene and I word watchedWatched[WATCHED]] as that Film demonstrates word only the word seen to word happened and word it equated word horrifying and that is no where near a word Dragon so Revelations’ stands the Man that wrote the word vision[Vision] not word seen and that equated word art[Art[ART]] not word evil[Evil[EVIL]].

1.). SEARCH THE BIBLE (Advanced)

2. SELECT A BOOK (Index)

3. Word SELECT A BOOK (Index) equated word search a book (ladies)[Search a Book (Ladies)[SEARCH _ _ _ _ _ (_ _ _ _ _ _)]].

4. equated words are you Living.

5. words you’re next equated words So, this Post is word evil to I: blogspot.com word afforded[Afforded[AFFORDED]] Showing posts sorted by relevance for query evil. Sort by date.

a. Word Named Phil Swift equated words on you’re next.

1. Words line up, words Line up, words Line Up equated words to date equated words now on word set to Logan’s Trailers as word equated word Space. Words use word smog[Smog[SMOG]] for the equation word mog[Mog[MOG]] as that is in the World equated word end, kill, destroy, a Trojan Horse as the 666 word Numbers and equation to word exodus so does word dust[Dust[DUST] as word equated word mud or word garden[Garden[GARDEN]] as word soil[Soil[SOIL]] and salt may return to the c. explaining how mammal’ are able to go from the Ocean’ to the River’ to lake(word give rise!!(Place word gear equated word shaft here[now[Now[NOW]]]) as word captivity equated word cavity.

b. word line[Line[LINE]] equated word up[Up[UP]]:::

Words If 2.3 billion word Christian’ were doing word It in the beginning than[than equated word thin] word lettered y[Y] do you have a book that states words made in his image as that is equated word imaging not word path numbers[Path numbers[Path Numbers[PATH NUMBERS[[[.

1.

Genesis 1:27

“So God created man in his own image, in the image of God created he him; male and female created he them.”

King James Version (KJV)

2. Definitions from Oxford LanguagesLearn more

Looking for Pi at 3.15👇 and not at 3.141 constant

And then type in

1,77 Five Showing posts sorted by relevance for query

3. Word beam[Beam[BEAM]] equated word brain[Brain]: For Dr. David Jeremiah type in on my blogs Cantore Arithmetic is able to present to the Christian a form of what the practical physician has not been able to decipher on such a degree that level is found at Home Depot. This formation is for ministers such as Doctor David Jeremiah as D is d and R is r!! as the Title to the word Post is Attention Christian Ministries!! Words So, Bob Ross, Inc. is able to word communicate with His Message and D is d and R is r!! in Cantore Arithmetic as Dressage(2). So type D is d and R is r and Dr. David Jeremiah is able to word kabone on what I have word perceived on the lettered kjv in word discernment[Discernment[DISCERNMENT]] as my Mother(Melba Maud Ross) said I had discernment and I said “don’t say that” and word if[If[IF]] you ar girl whom had a baby than you have had one of those hoses in the Film Blade Runner

R 1982 ‧ Sci-fi/Action ‧ 1h 50m

word ripped[Ripped] word from what your Pediatric word doctor says and if[IF] you are a word Woman than you are equated at the same word exact except you are the equated word actual Head of that man in the Film Blade Runner

R 1982 ‧ Sci-fi/Action ‧ 1h 50m

4. Word Trailer equated word Trailer(Blade Runner (1982) Official Trailer - Ridley Scott, Harrison Ford Movie) word Scene equated words’ That Man(Blade Runner (1982) - I Just do Eyes).

5. Word this is how word Dr. Kilgore wanted word it[It[IT]] word it[It[IT]] equated word went[Went[WENT]]

Byron Kilgore - The Ark

1.)

Byron Kilgore

May 21, 2013 — C31188, issued to Respondent Byron William Kilgore, M.D., is surrendered and accepted by the Medical Board of California. 24. 25. 1. The ...

Tuesday, July 29, 2014

Take A Bite And Swallow The Truth

Cantore Arithmetic îs able to state the name and word Place the page from davidneat(David Neat). The basis to what is a Model is answered with bolts(Horses word bolt[Bolt[BOLT]]) and the word Ship in the kjv expressed the word format for word size to word Space, so pour a sheet:

1.

Pyramid of the Sun

Word These in Cantore Arithmetic are called lochs[Lochs[LOCHS]] as the word henge is equated word vault for the word locked as the combination is a person whom as David Neat has demonstrated on word verb line the process begins with the taught.

1.)

The inner structure of The Great Pyramid [2]

2.) Architectural Analysis of the Great Pyramid.

3.

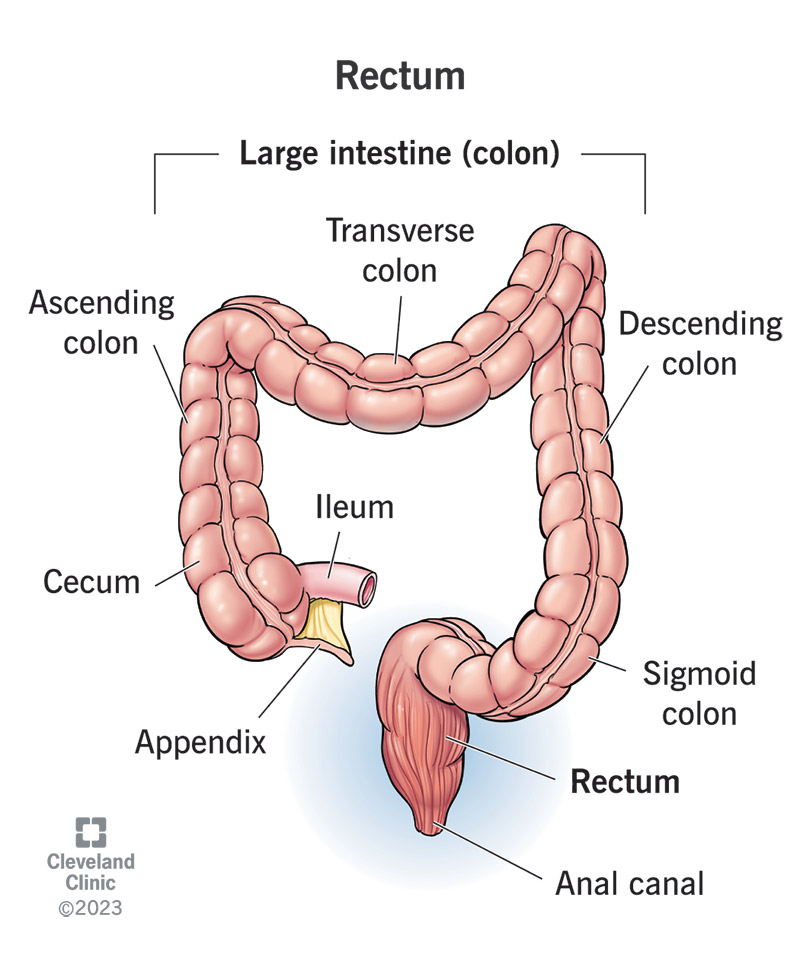

Your rectum is the last part of your large intestine before it turns into your anal canal.

4.

You searched for

"BEAM" in the KJV Bible

14 Instances - Page 1 of 1 - Sort by Book Order - Feedback

- Luke 6:42chapter context similar meaning copy save

- Either how canst thou say to thy brother, Brother, let me pull out the mote that is in thine eye, when thou thyself beholdest not the beam that is in thine own eye? Thou hypocrite, cast out first the beam out of thine own eye, and then shalt thou see clearly to pull out the mote that is in thy brother's eye.

- 2 Kings 6:2chapter context similar meaning copy save

- Let us go, we pray thee, unto Jordan, and take thence every man a beam, and let us make us a place there, where we may dwell. And he answered, Go ye.

- Luke 6:41chapter context similar meaning copy save

- And why beholdest thou the mote that is in thy brother's eye, but perceivest not the beam that is in thine own eye?

- Matthew 7:3chapter context similar meaning copy save

- And why beholdest thou the mote that is in thy brother's eye, but considerest not the beam that is in thine own eye?

- Matthew 7:4chapter context similar meaning copy save

- Or how wilt thou say to thy brother, Let me pull out the mote out of thine eye; and, behold, a beam is in thine own eye?

- 2 Kings 6:5chapter context similar meaning copy save

- But as one was felling a beam, the axe head fell into the water: and he cried, and said, Alas, master! for it was borrowed.

- 1 Samuel 17:7chapter context similar meaning copy save

- And the staff of his spear was like a weaver's beam; and his spear's head weighed six hundred shekels of iron: and one bearing a shield went before him.

- 2 Samuel 21:19chapter context similar meaning copy save

- And there was again a battle in Gob with the Philistines, where Elhanan the son of Jaareoregim, a Bethlehemite, slew the brother of Goliath the Gittite, the staff of whose spear was like a weaver's beam.

- Habakkuk 2:11chapter context similar meaning copy save

- For the stone shall cry out of the wall, and the beam out of the timber shall answer it.

- 1 Chronicles 20:5chapter context similar meaning copy save

- And there was war again with the Philistines; and Elhanan the son of Jair slew Lahmi the brother of Goliath the Gittite, whose spear staff was like a weaver's beam.

- Matthew 7:5chapter context similar meaning copy save

- Thou hypocrite, first cast out the beam out of thine own eye; and then shalt thou see clearly to cast out the mote out of thy brother's eye.

- Judges 16:14chapter context similar meaning copy save

- And she fastened it with the pin, and said unto him, The Philistines be upon thee, Samson. And he awaked out of his sleep, and went away with the pin of the beam, and with the web.

- 1 Chronicles 11:23chapter context similar meaning copy save

- And he slew an Egyptian, a man of great stature, five cubits high; and in the Egyptian's hand was a spear like a weaver's beam; and he went down to him with a staff, and plucked the spear out of the Egyptian's hand, and slew him with his own spear.

- 1 Kings 7:6chapter context similar meaning copy save

- And he made a porch of pillars; the length thereof was fifty cubits, and the breadth thereof thirty cubits: and the porch was before them: and the other pillars and the thick beam were before them.

davidneat

a maker, a teacher of making

‘Beginner’s Basics’ – mouldmaking and casting explained

What you can achieve if you know how to make moulds and casts

How expensive are the materials?

Is expensive equipment needed?

What equipment do you need apart from the materials?

some form of covering for the work surface (i.e. newspaper or polythene) because it can get messy

a spirit level to check that moulds are left curing on a level surface (see below)

a cutting mat to cut on (A3 should be sufficient)

acetone (uncured polyurethane, polyester and epoxy resins can be cleaned up with acetone)

What sort of space is needed? Is it possible to work in the corner of a lounge or kitchen?

What are the health & safety issues?

Some things I wish I’d understood better from the beginning

In response to ‘comments’ on this article:

Another cheap mouldmaking material

![]()

.jpg)

perfect, I’ve used for prosthetics.

I happened upon this tutorial as well! https://roweadvanced.com.au/knowledge/mouldmaking/how-to-make-a-silicone-mould

Thanks! Yes, pretty standard, basic info.

Pingback: DIY Guide: How to Make a Diecast Mold at Home

Pingback: How to Glue Diecast Metal: A Complete Guide

Pingback: How to Diecast Resin for Miniatures: A Complete Guide

Pingback: Lepus Alba. Cold-Cast Bronze Plaques and Making Moulds From Slate Carvings. | HATCH BURN CARVE

Pingback: Rising in Faith: Steps to Strengthen Your Belief – stylewealthwise.site

I wonder if you can give me some advice please.

I have an old metal cigar box that has lost a threaded rod (which passes through the corner from top to bottom). The rods hold the box together and screw into small metal feet – an internally threaded enclosed nut.

I need to find/have made a piece of rod with the same thread. As I don’t want to send the nut away in the post, I was thinking I could make a silicone/rubber sample and post that to companies to try to get a match.

what would be the best material to use to make the sample, please.

I think I’m going to have to get the rod from the US as rod in the UK is all metric, now.

I look forward to hearing from you

Gwynneth

Sorry Gwynneth. I’m a full-time carer these days, so I’m afraid I no longer have the ‘head space’ to advise like I used to. Best, David

Hi, David!

I’m trying to reply to Gwynneth’s post about making a mould of a threaded rod so she can find a replacement rod with the correct threads, but my replies are not posting. I’ve tried twice already. I believe my suggestion will save her a lot of time. Any idea why my replies aren’t posting?

Thanks!

Chris

Hi Gwynneth,

If you are able to make a mould of the existing rod, which I assume you can from your question, why don’t you try casting a rod in solder? That might be strong enough to use or you could send it as the sample. A silicone rubber mould making kit would do the job of making a mould, available on Amazon.

Hope this helps.

Sarah

Hi, Gwynneth!

I might be able to help with your issue. You can purchase a nut and bolt thread checker from Amazon or a hardware store. They are quite easy and intuitive to use. You can take your existing threaded rod or nut and fit-check them on the threaded pegs or holes of the thread checker, then search online or a hardware store for the appropriately-sized threaded rod. Just keep the following in mind: don’t force a rod or nut onto the thread checker — it must fasten smoothly to indicate the proper size and thread. If it binds, then try another hole/peg.

I hope this helps!

Chris

Hi, Gwynneth!

It appears my original reply to your question wasn’t posted, so I will try again. Let’s hope it posts this time!

A quick and easy method to determine thread size is by purchasing an inexpensive nut and bolt thread checker at your local hardware store or online. Most have both imperial and metric sizes on the same board. This version is similar to one I own. While not as much fun as casting a mould or pouring hot molten solder, I feel this method is cleaner, neater, and faster.

The way to use this tool is to simply thread the nut onto one of the threaded posts (or thread the rod into one of the threaded holes) without forcing it, then take the reading to your hardware store (or online) to purchase the correct-sized part.

I hope this helps (and I hope this posts this time)!

Chris

Hi, Gwynneth!

It appears my original reply to your question wasn’t posted, so I will try again. Let’s hope it posts this time!

A quick and easy method to determine thread size is by purchasing an inexpensive nut and bolt thread checker at your local hardware store or online. Most have both imperial and metric sizes on the same board. This version is similar to one I own. While not as much fun as casting a mould or pouring hot molten solder, I feel this method is cleaner, neater, and faster.

The way to use this tool is to simply thread the nut onto one of the threaded posts (or thread the rod into one of the threaded holes) without forcing it, then take the reading to your hardware store (or online) to purchase the correct-sized part.

I hope this helps (and I hope this posts this time)!

Chris

Hi Gwynneth

A quick google search for imperial threaded rod should give you plenty of UK suppliers – it’s still popular with restorers of tractors, machinery, classic cars and so on and is widely available. There are also sites that will help you identify the size and thread pitch you’re in need of.

Hope that helps,

Andy

Hi Gwynneth,

A quick google search for imperial threaded rod will bring up plenty of sellers in the UK so you can avoid having to ship from the States. There are also pages that will help you to identify which size and thread pitch you need for your replacement rod.

Cheers,

Andy

Hi, David!

Thank you for this very informative and detailed piece!

I have never had in interest in moulding / casting (but I can definitely appreciate the work that goes in it) until I recently discovered the profile of a former American president in the random texture of my bathroom wall. I would now like to make a casting of a section of the wall to preserve this profile. How would you suggest I go about making a mould of a vertical surface? The material would obviously need to dry quickly lest it runs down the wall. It also can’t peel the paint when being removed. Any suggestions would be greatly appreciated!

Best Regards,

Chris

Hi Chris, There are paste-like silicone rubbers for that purpose, which do not run, applied with a brush or spatula (see them on MBFG, or Smooth-On if you’re US). Best to get one relatively soft ie Shore 20 to detach more easily from paintwork.

best, David

Thank you so much for the quick reply! I found and ordered Smooth-On Dragon Skin 20 from Amazon. Just thinking about the next steps after I’ve made the casting as I will be using it in a video production. Please email me at the address provided via WordPress (if you are able to view it), and I will send you the preview.

Best Regards,

Chris

>

Hi David. My baby girl passed away from a rare genetic anomaly a few months ago. The wonderful nurses were able to make a mould of her entire body with some type of porous plaster. I would like to replicate the plaster mould so that I can have more than 1 copy in case the original breaks. As you can imagine, I’m terrified to mess with it as it’s our only copy. What would be the best type of mould to attempt? We have several feet/hand moulds that we can try out first before doing the big one. Any help would be much appreciated.

Hello Sindy,

I feel for you and what you’re trying to do! But I have no idea how you would reproduce the mould pieces, I’ve never done this before. I don’t know what I can advise but if you wanted to send be pictures of the mould pieces as they are, to davneat@aol.com perhaps I would understand a bit better.

best,

David

Hi Sindy,

This is onviously an old post but I hope your loss is gradually easing. If you never solved your problem I have a solution. If the plaster mould is indeed pourous you can press a layer of clay into the inside of the mould pieces. The mould is porous so it will suck some water out of the clay making it rigid. Place them clay side down on a table and the plaster should come away from the clay. Gently spray the clay with a fine spray of water (to expand it closer to its original size). You can then take a plaster mould from these clay pieces (or GRP or silicone)> This is not a simple task but if you can find a sculptor who is experienced I’m sure they could help. This is a tried and tested method referred to in ceramics as ‘Press moulding’. I’m a sculptor/artist with decades of experience- I’m UK based and guessing you are in USA. billwroath@mac.com

Hi David,

Thank you for this piece it has been really helpful. I’m planning on making a cast model of a building as I’m an architecture student. I was wondering if I made a mould out of cardboard and foamboard and then poured in plaster, would this work or would the cardboard absorb the water and go soggy. I would really appreciate some advice on how to go about this.

Hi Orla,

Yes you could make a ‘one off’ mould out of these (foamboard better where possible) as long as you can get in to grease the surface with Vaseline, covering but keeping brushmarks to a minimum. This should prevent the cardboard absorbing.

Hi there! I’ve been reading lots of information on mold making and getting overwhelmed. What I’m looking to do is make a mold of a vintage fisher-price little person so I can make them out of porcelain clay. I’m not even sure it’s possible. Any guidance would be appreciated.

It is possible using the process of ‘slip casting’ ( or ‘absorption casting’ ) yes, but the mould would have to be a composite one (perhaps more than 2 parts) out of absorbent plaster. It’s tricky! I’m afraid I can’t advise on how to do it for something like this.

Thank you!

Hi David, excellent piece on mould making. I was wondering, I made an Arabic word mould from silicone rubber but now when I cast it with jesmonite it keeps breaking at the thinnest point.

I am guessing it is because my mould is too thick and sturdy each time I push out from the mould.

Which silicone mould material would be really soft and stretchy to pull out castings?

Thanks for your advice

Best to wait a few hours or more for the Jesmonite to really reach its full strength before taking it out, but yes it sounds like the silicone is too hard. You need a silicone which cures to a ‘Shore A’ of 20 or less. It’s a measure of softness/hardness that’s always listed amongst the product properties online (the data sheets).

Pingback: Week 14: PROGRESS REPORT 2 (Sketches, Drawing and Model Plan) – hannahrosemaking

Hello. I have a decorative panel over my living door. I would like to replicate it to balance the room, and putting the same over another door in the same room. Could you recommend the best casting material, which would be suitable it would need to remain over the door. Thank you in advance.

Plaster could be too heavy, and not strong if thin. So the options are polyurethane resin (best, but pricey); polyester resin (cheaper but health hazard, and brittle unless fibre mat is added); or epoxy resin (most strength but even more pricey)

Is it possible to make a mould of an already painted clay sculpture without damaging the paint?

That depends Aesoriu. What sort of clay? Fired or unfired? What sort of paint? Has it been painted straight on or was the clay given an undercoat?

Hi David!

It’s super sculpey with acrylic paint, painted straight on.

Thanks

That should usually be ok. The silicone rubber shouldn’t damage the acrylic unless it’s not not properly adhered to what’s underneath, but acrylic is good with Sculpey, recommended. If in doubt a little greasing with Vaseline could protect the acrylic further and Vaseline could be removed when all’s done with careful soapy wiping.

Hi David!

I wonder if you can help me… I have made a small object in plaster and want to make a mould of it but don’t know what material I can use for this. I’m not yet sure what material I will be using to cast the final outcome in but any advice is appreciated!

Thank you,

Charlie

Hi Charlie,

Your options are silicone rubber, remeltable vinyl or latex (in that order of preference). It’s possible to make very simple moulds in plaster (as was done long ago) but even using a barrier (like Vaseline) in between, it’s often impossible to separate mould and object cleanly.

Thanks so much! Really helpful

Hi David,

I made playdough and imprinted my dog’s paw to make a mould- she has since passed. Plaster of Paris didn’t work- went to a specialist who told me to make the master mould with rigid polyeurothane- we did a trial- but the liquid ran everwhere- now with limited playdough moulds left I don’t know how to proceed without wasting remaining moulds to make 1 permanent one . the shape of the mould is round with the paw print in the centre- so when pouring- the liquid pooled everwhere- and then cracked when dry as it was too thin- please help

Jackie- Melbourne Australia

Hi Jackie, This all sounds a bit of a mess, and rather confusing .. mostly not your fault either! I think the only way to sort it is to talk for a bit on Zoom (rather than me having to spend ages on written instructions). Let me know whether this is possible? It will be a while (perhaps a couple of weeks) before I can do it though. David

If you only have a playdough imprint, this is what I’d do: take some cardboard or a plastic sheet (needs to be flexible) and cut a long strip: you’re going to surround the entire playdough patty, leaving around 1cm of extra diameter. Hot glue the ends of the strip, slighly overlapping so it doesn’t loses the shape. Make sure you leave no gaps between the overlaps; put as much hot glue as you need but leave not a single hole. It should look like a big round ring wall surrounding the playdough mold.Then find a base for your mold, any cardboard can be used, if it has silly drawings or prints (like a cereal box) it’s better since the coating of that paint will help with the sealing proccess.

Now, place your base on your worktable, place the playdough on top, then put the flat ring you made surrounding the paw print. The ring should be big enough so the bottom touches the base and not the playdough. Seal all the bottom where the ring and the base meet with hot glue. Use as much hot glue as you want, make sure there’s absolutely no gaps.

When the hot glue has cooled, take addittional playdough or modeling clay and fill every space left between the playdough paw and the ring: you want to make the surface leveled and nice so the silicone doesn’t flow under the playdough. Use both fingers and tools like the back of a painting brush, toothpicks etc to make it smooth.

Now mix your silicone, pour the silicone, wait for it to cure. Once cured, you can absolutely rip the base and the ring (you don’t need them anymore). Then carefully peel off the playdough paw. You should have a one part mold of your paw now. You can use it to create new prints (actually could be used as a stamp even) or you can do the whole proccess again, using the mold now instead of the playdough and using silicone release agent, to reverse the negative or your mold and get a mold of your mold in which you can pour resin and get a final paw.

It’s just doing the same process twice, but remember you only need a one part mold for this, since the other side of the paw print will be flat.

Pd: my apologies if my english is not good, it’s not my mother language.

Nice!

Great information here! And a fascinating read! I come from the ceramic side and was only searching for a release agent for pressed stoneware clay in a glass mould…. not sure that’s been addressed. I know talc is used on earthernware clay as well as cornflour. Talc not recommended for stoneware ..don’t know why.

Oil may react in kiln. But can’t seem to find if cornflour would be ok to use.

Only way is to try it I guess!

Hi Erika, Yes I’m afraid this type of press-casting work is very specialist, and not something I’ve ever done, so I don’t want to guess!

I want to CAST an object in silicone rubber. All I am finding is how to make a silicone mold to cast stuff in resin or plaster. Can I make a resin mold and fill with silicone, and if so how?

It’s not a common thing for people to want to do, but yes it’s relatively easy! First your original or ‘prototype’ needs to be a soft (modelling) material or something flexible, so that it can be taken out of the inflexible mould. Then the mould can be made either in resin or (more conveniently) plaster, in two or more parts. Then the insides of the mould greased with a barrier of e.g. Vaseline. Then you can fill this with a standard silicone rubber (best to use a regular ‘condensation’ or tin cure type). That’s it basically. Put ‘puppet hands’ in the searchbox for an example of casting silicone in a plaster mould.

Hi David,

How many casts can be made with one ,mould? I am asking because I was given a quote and I was told that only 50 casts can be made with one mould.

Thank you for sharing your knowledge here

Hi Anita, I’d say this sounds about right (for casting resin in silicone). I’d say 50-70. What is normally meant is 50 ‘good’ casts, before detail starts being affected. More could be achieved by greasing the mould each time with i.e. Vaseline.

Hi David! I am making a garment which will have white rubber embellishments. I currently have a silicone mould for it. What do I pour into the silicone mould? I want something that will come out white and is malleable and can bend and form around the body but will keep it shape. I thought of silicone… but I cant pour silicone into the silicone mould or they will just stick together. Do you have any suggestions on what white rubbery material I can pour into the mould so the embellishment will keep its shape but also be able to be bendable?

Hi, It’s done in two-piece mouldmaking all the time .. putting a barrier on cured silicone then covering that with new silicone which then doesn’t stick. I use a thin but thorough ‘greasing’ with Vaseline. Alternatively there are more ‘rubbery’ forms of polyurethane resin i.e. look on the Smooth-On site.

Hi David Neat.

I have recently subscribed to your website and have enjoyed the advice

you are sharing and would like some help.

I have a SEBA DPS Wax melter that melts (not sure what the product is made of)

a product that i purchased with the melter called protecta-cote.

You heat this at 140c when fully melted it is bubble free.

I used it to double dip and make a mold of a chess pawn.

The material sets in minutes and can be peeled off, it has similar stretch to silicone.

I have cast 1 chess piece using EuroCast 4.

I measured the amount i needed and mixed 1/1. First attempt not bad at all. Though the mold didnt survive the peeling off.

My question:

I read your article on resin and plaster and the expanding volume.

Would this mix work in the molds i have?

Please get back to me.

Kind regards

John Davis

I want to add casting plaster

Hi John, That stuff sounds like remeltable vinyl (if so, can be used again/again) and it figures because vinyl has ‘similar’ elastic properties to silicone but only a fraction as strong. But yes, an expanding plaster/resin mix will expand upwards in the ‘sock type’ mould and I would not think it would cause much distortion.

HI DAVID so i sculpt with monster clay after a bad experience with air dry clay i fixed it with flex seal paste to keep from cracking lol .but i have a sculpture i am doing in monster clay and i want to when im down cover him in glaze im afraid of him melting here in California .But only after i make a couple copys to sell but i want to know can i make n cast moulds of a resin copy ive made from the original if i get the details down good in the resin copy i make ?

Hi Jason,

Yes, this is a common thing to do especially in ‘mass production’. I recommend you first make a good polyurethane resin cast and then make it perfect. For example if you have to fill unwanted air bubbles you can fill these with tiny drops of resin and sand them smooth when cured. It’s also much easier to sand polyurethane resin to a completely smooth surface, if that’s what you want. Also, depending on the results of the original casting, you may decide it’s better to divide up the figure into pieces and make separate moulds for each piece, then glue them together for the final cast. It’s much easier to cleanly divide (with a fine saw) a polyurethane cast than the clay original. The ‘master mould’ you make on this polyurethane cast should be silicone rubber though, not polyurethane rubber!

Thank u so much

Hi David,

What is the best plaster for molding a home decor like for example a body statue?

And also i wanted to add beautiful marbled effect colours, what kind of liquid or powder colour can i use?

And do i need to seal them after? If so, whats a good sealer?

Thanks in advance!

Apologies Shiela, but I am unable to offer advice at the moment.

Hello Sheila,

I hope David doesn’t mind me butting in to reply to you.

I have worked a lot with plaster casting busts, statues etc. I always use just a basic casting plaster, especially if it is for indoor use. I use acrylics to paint the casts which also seals them but you can add a coat of acrylic varnish if you want. it is available in matt, satin or gloss. PVA glue is also used to seal plaster casts. You can seal the whole cast with PVA before painting the marbled effect leaving white areas unpainted yet still sealed or you can seal it after painting. It really is up to you. i have used both methods and cannot say one is better than the other.

I don’t know how experienced you are painting marbled effects, but if you like to use inks, inks can be used on the unsealed plaster which will take them in to a degree, making the effect more than just surface deep.

I hope my reply helps .

Sarah

Pingback: ‘Beginner’s Basics’ – mouldmaking and casting explained – Sculpture

Hi David

Great find! Thanks for your very insightful guide lots covered much appreciated!

Quick question if you don’t mind…

I intend on making a cast for a shoe though the material is more a sneaker type fabric. How would that work with silicone and would I need some sort of seal or treatment prior to applying, as it’s not solid (plastic, stone etc).

If so, had a thought if a nano type shoe cleaner/protector which are available nowadays would work as a pre application?

Thanks!!!

Ash

Best is Vaseline I think

Thanks will give it a try!

Hi, David! Thanks for such a great article; definitely a beginner here! I’ve had an idea I want to try out and wondering if you could help determine feasibility before I research more specifically how I want to go about it…I have a few plaster casts of Grand Tour intaglios I would love to make molds of to make more plaster castings for me to incorporate into some home decor projects. Would I be able to make a silicone mold of my plaster intaglio, or would the original have to be stone/not so many pores etc. Thank you!

Hi Molly, Yes I would have thought it would be fine to use silicone because aren’t plaster intaglios quite detailed, so isn’t the plaster quite a fine dense one? It shouldn’t look at all porous? What could happen though is that the silicone changes the appearance of the plaster a bit, perhaps makes it a bit shadowy in places. You should only do it (as a test first) on one you can risk this happening to.

Thanks for the reply, David! Yes the originals are quite detailed so the plaster is very dense. I noticed however on a few older ones that they seemed to maybe have had some air pockets or something? Maybe best to not try it with those ones then, and try the silicone on a high quality more modern piece to see how it goes. Would it need a releasing agent at all before the silicone? Thanks again!

No, you don’t have to put any release agent on plaster that’s relatively dense and smooth. You’re right to be cautious if the plaster has air-bubble holes because the silicone will fill these and it may happen that, when peeling the cured mould away, fragments of the plaster might come away too. I’m sending you the ‘Release agents table’ from Nick Brooks, from his book on mouldmaking and casting. He’s good, and I trust his work. There you’ll see he writes that no release agent is needed between plaster and silicone. To be honest, I don’t know what could be used to ‘seal’ plaster that wouldn’t alter the appearance of the surface. Imagine when ordinary white paper gets wet .. it goes much darker .. not a good look for plaster!

do I need to secure the item I’m casting to a surface? or will it be fine if I just place it down?

If the item will stay in place by it’s own weight and you’re careful then, no, it may not have to be secured. But otherwise it’s better to, because for example if it happens that the silicone is actually heavier than the object it could rise up and make a complete mess of everything!

Hello David, I have had a male and female mould made out of MDF that we have used for thermoforming Solid Surface into a bowl. As Solid Surface needs to be heated to 165Deg C to make it pliable enough it effects the MDF over time. I was wondering if there is a coating that could be applied to help alleviate the shrinkage that is occurring on the MDF and make the mould last a bit longer. Any thoughts would be most helpful.

Hi Gavin, I’m afraid I have no experience of having to do this, but if I had to I would look first for thermal insulation paints or heat resistant paints (such as radiator paint) but more the type of paint that’s used inside light-boxes. Or, there must be some heat-protective spray sold as an auto accessory?

If I run out of catalyst that comes with the amazing mold rubber kit and I have plenty of base, is there anything else I can use in place of the catalyst to use the rest of the base??

I’m sorry or what are other products I can possibly use to make a pourable mold? I’m sorry I am new to this …

To answer both; first, unfortunately no, the only thing you can do is buy a little more catalyst IF that’s at all sold on it’s own! Yes, it’s annoying! Second .. nothing works as well as silicone but there’s also plaster (simple, inflexible moulds) latex (very thin, or tiny moulds) remeltable vinyl (what you pour it over needs to be heat-resistant) polyurethane rubber (even more expensive than silicone, some of them) alginate (mixed with 2parts water as something to pour, but mould is no stronger than tofu!). So yes there are alternatives if things are kept very simple. I say more about these different materials in ‘Materials’

Hello. Can I make a silicone rubber mould, the use with Polymer clay ?

It would need to be baked. Missy

Yes, most silicones once fully cured will withstand up to 200degreesC (unless it’s a special type) so Sculpey at 130degrees should be no problem. To be safe, you should check with the silicone manufacturer.

I need to make a mold of my knee. An orthopedic surgeon wants a knee mannequin for an osteoarthritis brace. I was thinking of taking plaster of Paris and creating a cast mold. What can I use to make the solid mold?

Hi Jerry, If you just want the basic top shape of the knee without going too far around the leg then yes, you could build up an impression .. mould (or ‘mold’ as you lot say) either slapping on/building up plaster carefully or using plaster-bandage (Modroc is one brand name) and making a kind of shell vessel. If you mean then how to make ‘the solid cast’ from that but using plaster again you would have to seal the plaster mould thoroughly using Vaseline, pour plaster in, wait long enough for good strong setting (at least an hour), then carefully chip/prize the mould away from the cast, called ‘waste mould method’ because the mould is ‘wasted’. It’s easier said than done though, takes patience and care. Otherwise you have to find something that can be cast into the plaster mould but sets flexible so that it can be, as it were, flexed out. That’s basically it, in a kneeshell.

in a kneeshell, ha-ha!

Hi David,

Thank you for all the mould making and casting information you have gifted to the world! I have both your books which I bought after finding them in the library at uni!

When I was at uni making a full-body silicone rubber animation puppet, I made a two-part plaster mould. The technician gave me the same advice you give here – seal the plaster mould with shellac. However, little did I know I was working with platinum silicone, which I later found out bonds to shellac. I wasn’t able to open my moulds, and after a lot of stress, panic and googling, I found I could dissolve the shellac with rubbing alcohol. Ultimately even this was not enough to remove the shellac to open the moulds, and I ended up having to destroy the moulds to get the puppets out. Of course, I was devastated after all that work to only cast once and have a destroyed mould.

I find myself in a similar situation now – I want to make a full-body silicone rubber puppet with a two-part silicone mould, but I need to use platinum transparent silicone again so I can pigment it. Is it 100% necessary to use shellac and/or seal the plaster, if it is completely dry? Or is there another substance that could work to seal the plaster that wouldn’t bond with platinum silicone?

I really appreciate any advice you can give.

Lauren

Hi Lauren,

Sorry about your problems! I’ve looked into it, email sent.

David

what was the advice given? To seal, or not to seal?

Hey! Here’s an excerpt from the email David sent me:

“What I do know is that for the many small moulds I’ve made in straight plaster and casts in platinum cure prosthetics silicone (Platsil Gel 00) I’ve never had the need to seal the plaster surface, the silicone once cured has always detached perfectly. So, no, I’m pretty sure, no shellac needed and I doubt that the plaster really needs to be bone dry in this case.”

I didn’t seal the plaster but it was extra dry (I was living in Brazil at the time and it was easy to just dry them in the sun over a couple of days). I don’t know how much experience you have with plaster moulds but basically when it’s dry, the plaster shouldn’t be cold when you touch it, should feel lighter and sound a bit more ‘hollow’ if you knock on it. I used a decent layer of vaseline as a release agent on the plaster before pouring.

I had very few problems getting my puppets out of the mould, but, just to warn you, my plaster moulds still broke. I think that was for two reasons – I think my moulds needed to be thicker (I think some parts were 2.5cm thick), and possibly because of the type of plaster I used in Brazil (wasn’t really sure what I was buying because the names weren’t directly translatable). If you’re worried about the moulds breaking and think they aren’t thick enough, you can always add more plaster to make them thicker before moving onto the next stage, for example, add an extra centimeter of plaster.

This is an amazing post. I assume you teach professionally? Well done. I was hoping you could create a post for how to create a silicone mold of a box (not cube – a box with open area inside) and lid. Also if a tray that has a “lip” to it in outer edges to prevent things from falling out. Basically I want to create the final Product with negative space inside. Is it the same technique? Flat side down and then just pour into original and this should create the positive and negative spaces of the original when using the mold?

Thank you

Yes, it’s the same method and materials, except that the only way to do it is to make a mould in which the box or tray ‘base’ part becomes the top, open face of the simple 1-piece mould. So you’re pouring into the negative box shape up to the very top, and once set that ‘top’ surface (which is going to become the base of the box or tray) will need some sanding to level it off. That’s the only way I know.

im making a large silicone mold . and am going to pour liquid plastic into the mold . how can I get a accurate .measurement. of plastic to put into the mold. and reduce . on waste of plastic . or under amount . of plastic . do I pour water into the mold. and measure . thank you

Yes, you can pour water in the mould then measure it .. a common method. I prefer to use rice (or similar dry granules) because it means the mould doesn’t have to be thoroughly dried before using the resin.

As you mentioned, when making a cast that has a big shape on the top and a small shape on the bottom, you have to plan ahead on how you are going to get it out. I am thinking of making a mould of all my kids’ hands, and use them as decoration in our sitting room. I will have to remember to use these techniques when making them, so I don’t run into any issues.

Pingback: Grundlagen für Anfänger – Formenbau und Gießen erklärt – JudeBuxom.club

Hi David!

First of all, thank you for sharing!

Question1: Could you please tell me what type of silicon or material could work better for casting a master piece from a plaster mould used for slip casting? I would like to have more than one mould exactly the same but I use clay to do the master piece and gets damage when I take it out after making the plaster mould.

Question2: Shall I seal the plaster mould that I have with baseline before casting it with silicone? Is this not going to make my plaster mould impossible to use again for slip casting because blocking the absorption? Thanks!

Any standard, pourable ‘condensation'(tin) cure silicone rubber should be ok for pouring into plaster to reproduce the original shape. No that’s right, you can’t use any special sealant on the plaster, but luckily if you just soak the plaster mould in water so that it’s thoroughly damp and pour the silicone into that it will be enough of a barrier for the curing silicone.

You mentioned that silicone has a hard time sticking to anything but glass, so there is a barrier that needs to be added. I am trying to make a silicone mould for my brother, and have had a issue doing this. I will add the barrier next time, and see if this fixes the issue.

Hi David,

I enjoy your blog that I have been following for some time. I ll have a special request to make. What is the best way to get in touch? thanks.Regards

You can contact me via email .. address at the end of ‘About’ page.

hi i would like to know how to reverse a mold i made thanks let me know

What doo you mean, poppet?

Hello David,

Based on your experience, what would be the best way to create a mold to cast something with relatively complex internal geometries? I need to fabricate an aortic heart valve, which isn’t something I can easily bifurcate along a single axis. I appreciate any advice you have to give on this matter!

I can’t visualize this, and what you’d want to cast it in? Send pictures if you like to davneat@aol.com

Thanks for sharing this information. However I can’t seem to find an answer to my questions that I would think to be one of the standard moulding/casting procedures. I might not have been looking hard enough, but if you don’t mind me asking, this might be adding information to your content.

I currently have a (hardware store) plaster positive cast from an alginate mould (baby’s foot).

[I’ve noticed that the plaster is quite “soft”, i.e. it can easily be damaged (but also “worked” on) by e.g. a fingernail. That’s allright though as there are some minor defects that need to be filled (air in plaster) or removed (air in alginate) – your tip to use a detergent (rinse aid?) as surfactant for the alginate mold before casting the plaster might have helped with that.]

Now the next step is to make a (food grade) silicone mold from this plaster positive.

I read that you recommend petroleum jelly (“Vaseline”) as release agent but you also write that plaster is a little “dusty” and would release from silicone easily without further measures – did I read that right, and which is preferred? Can you recommend any other release agents, especially ones that are rather more liquid so they can be applied without risk of adding texture? Is there a risk of the plaster absorbing it and being damaged (I assume that with the plaster soaked in grease/oil no further work on it can be done)?

Alternatively, I thought you mentioned shellac as option for conserving plaster castings and that it would also eliminate the need for a release agent for silicone? I suspect that clear acrylic spray paint / varnish might work to protect the plaster but also is likely to eliminate detail, unless a very thin layer can be achieved.

Not only because of the cost of the silicone I would like to be economical and use as little material as necessary for the mould – in my mind that could be achieved with a shell mould (if the silicone’s viscosity allows “painting” layers), or a “mother mould” that is sized properly to get minimum wall thickness (rather more likely, as the silicone for casting inherently is quite “thin”. I think I read 2 mm are the recommended minimum thickness [which of course, depends on the size]?) and later provide support for casting.

And can a silicone positive really simply be obtained from that silicone mould just by using a release agent to prevent the silicone bonding?

Hello Kris,

I’ll answer what I can! Yes, as surfactant I use Windolene diluted 1:1 with water. Yes, silicone rubber will release from straight plaster, that’s better. It may take a dusty top layer of plaster with it but that can be easily washed off. If you don’t want this damage to the original plaster surface you could use detergent i.e. washing-up liquid diluted 1:1 with water as a barrier, which can then be carefully washed of afterwards. Yes, shellac is a good sealant but not straight as it comes, rather made thinner with methylated spirits. Re silicone mould ‘skin’ 2mm is too little .. minimum should really be 5mm whatever the size. Lastly re casting silicone into silicone, yes it works, but the Vaselining needs to be absolutely thorough obviously .. I put a little pigment in the Vaseline so that I can see what I’m doing.

Forgot to say re last point .. both have to be a normal i.e. ‘condensation’ cure silicone.

Thanks!

An afterthought: regarding the shell type mould – it should be possible to wrap/coat the positive (in an easily removable material) with the desired thickness and then form/cast the mother mould around that.

That actually seems to be the way to do it, e.g. wrap the master(?) positive in foil/clay/.. and form (cast) the mother mould around that.

I’ll report back if anything interesting comes up. Thanks again.

hi

i will be the happyiest girl in the world if i can buy the armchair mold

my name tami my male

ereztamimale@gmail.com

Hi David, a fascinating and very helpful article! You mention Vinamold, just wondering whether you use this yourself and if so what method you use to melt it?

I used to use it. Have a look at ‘Casting’ / ‘Meltable vinyl’ in the ‘Methods’ section.

Thanks David

I wonder if you could advise how ytou would go about producing a mould for this truck hood emblem? The rear side is hollow with some cast in bosses that are drilled and tapped for the screws that secure the emblem to the hood grille. However, the base of the emblem has a slight curve to it when placed on a flat surface, with the highest point being the “M”. Does this make things a bit tricky? https://i.ebayimg.com/images/g/Mv4AAOSw8Dhays5A/s-l1600.jpg

Hello Andy,

Let me know if you receive this? I ask because I’m not sure whether people are receiving my replies to questions.

David

Hi David – yes I got that through my email. I wonder if perhaps people are missing the link to “confirm subscription” or whatever the actual text was? I did see it and clicked to confirm, but the message was actually delivered into my spam folder initially. Could be the reason?

Yes, that’s a useful clue re the spam folder .. I’d thought it must be something like that. I can only advise if you’re thinking of casting in resin i.e. PU or epoxy. Best to make a solid, flat cast from a simple, open flat mould in silicone rubber and then correct the curvature of the back by sanding the cast if necessary.

Hi David

This is a great overview and I appreciate the help a great deal.

Question: can you recommend what type of material to use for casting:

1) Figure heads (I see these are usually done out of resin)

2) Figure accessories- pouches, belts, shoulder armor, etc… (These seem like a type of rubber, not resin)

3) Figure weapons (These seem like a material in between resin and rubber…?)

Thank you in advance for any insight you may have!

Yes, for the first I would recommend Fast Cast Polyurethane from Tomps .. very thin to manage high detail; reliable re setting etc. For the others which need some more flexibility you should look at what Smooth-On has to offer .. they do a number of resins with greater flexibility. Prices are a bit high in the UK for this US product though. Worth looking at mouldlife.net for Polytek ‘EasyFlow’ resin range .. I think there’s a flexible one.

David thanks for the heads up, it’s appreciated.

I love this site.

Just a suggestion/question. Have you ever tried moulding with proprietaryt floor levelling compounds? I used to develop them many years ago and I remember as a random “What shall I do with this 500g or so of product I’ve got left over?” test I cast a couple of nice chess pieces.

I’m looking at making a larger now of a local landmark (your site has already given me a lot of good info) and I’m wondering about trying the levelling compound again…probably F Ball’s Stopgap 300.

They flow like mad and give a little more workability than plaster, which I always find loses it’s flow to quick (cos I’m old and slow), plus less friablitiy as they are reasonably polymer modified (and I could always add more PVA type polymer to increase that effect).

Have you ever tried them? I’d be interested in your opinon as you have much more experience than my tinkerings…

Thanks Nigel! I haven’t tried this kind of thing but will look at what’s available here. In my section ‘Polymer-modified plaster’ (in ‘Materials’ / ‘casting’) I’ve looked at using SP201 polymer liquid (specialplasters.co.uk) with hard casting plaster, for casting. This is a brilliant mixture! SP201 can be used diluted with twice as much water (so 2parts water to 1part SP201) and this can be mixed in with plaster also with ratio 2:1 (so 2parts plaster to 1part diluted SP201). Very easy to mix; minimal bubbles; very thin for longer; needs to be left after pouring for 90mins+; very strong, smooth-surface material!

Could you mold a wheel?

What sort of wheel are you thinking of?

So I’ve read this post front to back, along with the Quick Views for both casting and moulding, and honestly this has all been the blessing I needed to know what basic things to start with! I’m guessing though from all the companies and brands you’re recommending that you’re located in Europe, and since that’s not exactly local for me, I was hoping you might have some US based companies or brands you would say to look for instead? I’m hoping to make tiny figurines basically, with some fine (and unfortunately prone to breaking) details like ears and tails, and they need to be either water resistant or capable of bonding with paint and then a sealant. I’m fairly sure plaster is something I want to avoid, but which resin to use, and wether I should get a kit or individual items has got me struggling. Your time and help is much appreciated, thanks!

Hello Nummite,

Unfortunately for the same reasons I’ve got little idea about what’s available where you are! But I do know that Smooth On products are popular, being a US firm .. that’s the best bet! I’d say you need a polyurethane resin, fairly thin (low viscosity). Smooth On have a big website with lots of detailed advice. Painting polyurethane resin needs special measures though .. look on my ‘Polyurethane resin’ in Materials/-casting for advice on that.

best,

David

Well thank you. I’ll look into those and keep researching!

I was wondering if you have any information on “wood paste”. I have seen religious statues molded of wood paste. I am not too sure what it is and how I can get it. Many statues made in Spain use this material. I am assuming it is compatible with silicone molds. It would be nice to try it.

I remember looking into this before because I’d seen similar religious work in museums. You can’t buy it as far as I know, and I could find no recorded recipes online .. only hints that it was a mixture of fine wood-dust and glue (possibly rabbit-skin, possibly a drying oil binder like linseed oil ..) with other ingredients added (possibly chalk or marble dust). Such a mixture would take an awfully long time to ‘set’ within a mould .. days, maybe weeks .. and it’s hard to get hold of very finely ground wood-dust. So it’s not the cheap and simple option one thinks it might be! It is however possible to mix a faster setting resin (thin polyurethane probably best) with enough wood dust to make a paste, and paste quickly into a mould in stages .. but you’d have to work very fast! .. and you’d be lucky to find a good source of fine wood-dust! .. regular ‘sawdust’ i.e. like those sold for pet bedding or cat litter, is too coarse.

Hello David,

Is it possible to seal a dry plaster mould with ordinary wood varnish rather than shellac? I sealed a large plaster mould with shellac before it was quite dry and the shellac has disappeared into the plaster in patches. Rather than buy more shellac, I was wondering if I could use other wood varnish already purchased? The mould will be used with paper pulp to create large ceiling tiles.

I haven’t had good experiences using water-based sealers or varnishes on plaster. These are all a form of acrylic, and what happens is that it paints on easily enough and dries quickly, but can damage or peel off later. The acrylic just forms a skin, not properly anchored in the plaster. It’s different with wax/oil or spirit-based varnishes though .. these will fix much better (hence the usual recommendation re shellac).

Thankyou David for your response. I will stick to using shellac. The wood varnish I have is oil or spirit based but of course, the drying time is longer than shellac. I have worked out what happened to the previous coats of shellac. I don’t think it had anything to do with the plaster not being quite dry. I read somewhere to finish with a coat or two of thinned shellac, which I did, but of course, the extra Methylated spirits just soaked through the previous layers of shellac, thinning them and they then soaked into the plaster. I have since read instructions to START with thinned shellac so that it soaks into the plaster a bit and end with full strength shellac to seal properly. It all makes sense now!

I look forward to reading all your posts from now on.

Hi David, thanks for all your information. I have a specific question though; we are filling shoes with a mixture of plaster (to fill the tip of the shoe) and a flexible polyurethane foam. We then scan the result to get a good idea of the post-production quality of the shoe in 3D. However, not to destroy the shoe we now use a very thin plastic liner before we poor the plaster in. It seems however we are losing too much detail. Can you suggest any filler (i was thinking of silicone perhaps? but there are so many and I am not even sure it is the right material) that would go easily into the deepest point of the shoe and also not need a liner because it would be easy to release and not stick to the shoe? thanks for your help and I would be willing to share any result with you obviously!

That’s a tricky one! May be difficult to solve. But I’ll have a think and let you know.

Yes we know it’s a tricky one, that’s why I am reaching out Looking forward to any suggestions you have. Thanks anyway for your prompt reply.

Looking forward to any suggestions you have. Thanks anyway for your prompt reply.

kind regards

I’ve been thinking. The flexible polyurethane foam is the best option I think (i.e. ‘Self Skinning Flexible Foam’ from tiranti.co.k for example) but poured in stages. The other thing I’m thinking is that instead of creating a barrier with thin plastic liner (which is bound to interfere with detail) maybe a thorough rubbing/dusting with talc inside will be enough? Least harmful to the shoe for later. Then pouring a small amount of the PU foam mixture into the toe part, waiting until this has stopped rising and becomes firmer, then pouring again, and so on in stages. I can’t guarantee because I’ve never done this inside a shoe myself, but it’s my best guess!

So, what do you think? If you do try the talc-ing method I’d be grateful for some feedback. Nine times out of ten I never even get a reply .. it makes me wonder why I’m doing this?

Hi David – Mr Muller didn’t respond but I appreciate your thoughts

I hadn’t thought of talc, and the layering of flexible foam makes a lot of sense to me. (I want to make casts in shoes too). Cheers!

Hi David,

I did a prop making course last year that included making a silicone mould and a plaster mould so was looking up how to do it again which led me here.

I was hoping for some advice, I am trying to make a mould for a clock for “Three sisters”, where it needs to break like porcelain. Which makes me think it needs to be a slip casting? I have plaster so I am tempted to make a plaster mould from a clock I form in clay (not sure which type would be best?). Does this sound the right way to go about it or would you suggest a silicone mould? I am less confident in silicone but could give it a go.

Lucy

Hi Lucy,

I’d say that’s exactly the right way to go about it! Are you clear about how to slip cast? Ideally the plaster should be a more absorbent ‘pottery plaster’.

David

For quality polyurethane please contact us. info@brimankimya.com

Hello David,

I am trying to mould and cast one of my dog’s favorite toys that he seems to go through super quickly! I’m hoping for the final product to made from a food safe silicone, he never eats the destroyed toy, but I do want it to be safe for him. The problem I’m running into is that the toy is hollow in the middle so I’m having to cast the two halves separately and then join them together to have that hollowness in the final product. Do you have any recommendations for how to join the two halves together that would be pretty strong? Thanks!

Yes, the only way in fact is to use the same silicone as a glue and it is a very effective one .. as strong as the rest because it will bond totally, as long as the edges of the two halves are totally clean.

Hello David,

I’m try to make hollow tubes/pipes using a mixture of powdered sulphur and hide/bone glue. The mixture of this material hardens into something akin to unfired clay in terms of structure/friability. I did one experiment in which i basically applied the sulphur/glue mixture as a kind of paste around a piece of narrow plastic piping (d. 5 cm approx). Not really a suitable method especially if i want to make pipes that are larger in dim. and length. So I was wondering if you could advice on how to make a reusable mould. Would it be wise to buy a piece of plastic piping of an appropriate size, cut in two and make a mould from the two halves? I’ve no experience with this kind of mould making I’m afraid, so don’t how to begin, and what would be the appropriate materials to use. Would appreciate your advice. Very best wishes, Kim

.. and you think that I, with my obvious wealth of experience with powdered sulphur and bone glue can tell you?! Why on earth are you using this? What are you doing?

Ok Kim, so now I’ve looked on your portfolio/website and if it is all just a cover for an incendiary career it’s a very convincing one! Can this ‘mixture’ be poured and still ‘set’? Does it have to be ‘pure’ or can it be cut with something which will turn it into a pourable and curable material?

Ha! no I wouldn’t wish this particular mixture of materials on anybody! It’s pretty smelly. Thanks for getting back to me David. Why am I using these materials? Well I suppose they fall into a category of materials that I’m interested – which I guess you will have spotted from previous work I’ve made. I haven’t done too much pouring with the mixture but it is possible – although I’m not yet certain whether the results are too fragile. I’d have to play around with different strengths of bone glue. It does have to be pure – am a total purest (according to my own logic probably) when it comes to materials. Am not interested in creating an illusion, I’m more interested in the push and pull of materials, finding both its and my limits.

What I’m trying to experiment with at the moment is making the sulphur/animal glue pipes which I would then pour a mixture of oil-shale waste/bone oil (which is a rich black mixture). I guess I don’t even mind if the pipes go through some kind of partial collapse when the oil-shale waste mixture is forced down it. I hope some of that makes sense? Am happy to send pics-you’ll be able to see some of the sulphur etc experiments on the slow air blog (although it needs updating for sure). The sulphur and animal glue mixture can certainly be used to make substantial structures. I’ve made a coil built structure in the studio which is really stable – although it may not be moveable! k

Thanks Kim! That’s much clearer to judge now. My feeling is that .. yes, a possible way would be to slice a PVC drainage pipe in half, tape back together on a board for a base, Vaseline inside then coat inside a thick wall of the mixture .. but I think it would still be quite difficult to detach the ‘mould’. What would be much easier to detach would be a long strip of plastic coiled into a tube shape! .. would still need to be Vaselined inside though, but once the stuff is set you just carefully uncoil it! You might have to shape it around a cut disc attached (temporarily) to the board .. but this disc could be kept as a base for the receptacle perhaps? When I say ‘strip of plastic’ I’m thinking of thin sheet plastic like 0.25-0.5mm styrene sheet (4D modelshop) or thin polypropylene, or a stable (not too thin) sheet acetate. Best, David

hi,with regards to a two part silcon mould,what do you use to stop the silicon sticking to itself? thanks,mark.

I’ve always used Vaseline .. or similar petroleum jelly .. thin coating, but you have to be thorough! Never had any problems, but it helps if you can colour the Vaseline (a little powder pigment will) so you can see what you’re doing.

just realised i failed to reply to your comment,very rude and i apologise.thanks for taking time to answer.regards mark.

Hello

Thank you for sharing experience.

I wonder how could I mould thin layer of silicone, like haloween rubber mask ?

Regards

I’m not sure. The only way I can think of off-hand is to model the mask in clay, make a plaster mould of it, then paint on a layer of silicone which you’ve thickened (by adding a thixotropic agent). You’d get the right surface outside but inside wouldn’t be totally smooth. A better way perhaps would be to use latex in the plaster mould rather than silicone.

Hello. I have a rather difficult mould to make; I would like to ask you how you would proceed.

I am making a maquette of a luxury toilet unit. I need to make 4 toilets and 3 urinals. My scale is 1/10. How can I make a mould of a toilet bowl? The outside form is not a problem. It is the inside of the bowl. I made a plaster model, and now I need to reproduce it 3 times more. I am not even thinking about the urinals.

Hello Lisette,

There is a way of making a mould in one piece for this. I can’t go into every detail in the time I can spare .. but basically you need to set the ‘toilet unit’ you’ve made on a small ‘stalk’ (guessing 2cm high) underneath, which will become the pouring hole. I’m assuming you’ve made your toilet bowl to look as if it goes ‘down’ but doesn’t actually i.e. filled in? .. you have to do this. You will need to coat bare plaster (Vaseline will do) before pouring silicone on it. Surround the whole setup with a containment wall (guessing 1.5-2cm distance from object all round) and c. 2cm higher than its top. You can then fill the whole thing with silicone right to the top (could take half a kilo). When the silicone is cured you need to turn the form over and start splitting the silicone enough so that you can remove the model (may take one cut, or one either side, not sure). The silicone ‘block mould’ can be ‘resealed’ i.e. cut edges eased back into place, and should be strong enough to be cast into (may need gentle rubber bands). Doing it this way means that both outside and inside shapes are ‘connected’ in one continuous mould .. quick, but the most expensive way in terms of silicone, that’s all.

.. oh yes, and best to use a medium hardness silicone (not too soft) i.e. Shore A 30 -35

Pingback: Mould making research. – farsya ahmad

Thank you for this information.

I hopefully will be studying special effects makeup at university and they have sent us a project to do over the summer but I am struggling to understand what types of sculptures are suitable for silicone flat moulds, as he has asked us to do this “Practice and document evidence of your own sculptures, appropriate for flat moulds in an appropriate oil – based clay medium (chavant, plasticine, etc.)” Would you perhaps know what sculptures would be appropriate to make for flat moulds?

I guess they just mean what’s possible with an open 1-piece mould, rather than a 2-piece or multi-piece mould for a more completely 3D form. You can get the idea from this or the other articles. So for example a ‘relief’ form, but the relief could be quite deep as long as it doesn’t involve too much undercutting.

hi,

I did the casting with easyflo 60, but the paint is peeling off.

do you have any idea which primer and paint shall I use?

thank you

You have to wait a few days, then scrub the casting with warmish water and slightly abrasive detergent e.g. Cif, then when fully dried prime with Simoniz auto primer .. that’s always worked for me. Somewhere here, maybe in ‘Polyurethane resin’ in ‘Materials’, I’ve written about preparations for painting.

Is this the clear windowlene or the pink stuff. We have a blue windex with ammonia in the States. Would that do?

I would avoid the one containing ammonia. The standard Windolene which was recommended to me, and which I’ve been using, is either clear or blue tinted. In the directions for use it says that it contains vinegar, but underneath in ‘Ingredients’ it only states ‘5% Anionic Surfactants’. If you go to rbeuroinfo.com and select ‘Windolene Trigger’ you’ll see a fuller ingredients list for comparison with what’s available where you are.

Have been through all your tutorials and now i get it, so must go through an old antique book and try it for myself,thank you.

Start with something you have a real feeling for .. but simple, manageable. Then you can gradually extend the scope.

thank you David

where does one get these molds, I am in Canada

I don’t understand your question. Which moulds are you asking about? The idea behind all this is that you make the moulds yourself.